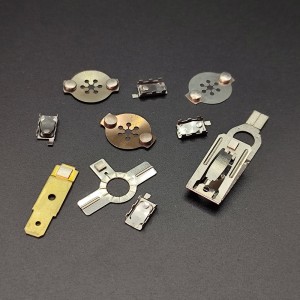

Automatic Contact Rivet Assemblies

Application

Silver contact in-die riveting is a special riveting method that creates a permanent connection by applying pressure between the application and the parts being joined. Compared with other types of riveting methods, silver contact in-die riveting has the following advantages:

High reliability: In-die riveting of silver contacts can form a high-strength and reliable connection, ensuring stability and durability between connected parts.These in-house machines offer unparalleled integrity in the riveting process throughout a production run which is paramount to prevent heat rise.

High precision and consistency: Silver contact in-die riveting can achieve high-precision and consistent connections by controlling the force and time of the riveting process to meet strict engineering requirements.

Improved production efficiency: Compared with traditional manual riveting methods, silver contact in-die riveting achieves efficient production efficiency of 300 parts per minute through automated equipment, improving production efficiency and product quality.

Our products are widely used in low voltage electrical equipment, electronics, telecommunications, home appliances, relays, switches, thermastat, and other areas, the Group mainly serves Fortune 500 companies,like, Schneider Electric, ABB,Omron, Tyco, Eaton,Tengen, Xiamen Hongfa and other world-renowned Electric Company.

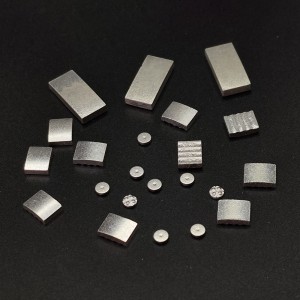

NMT provides full integrated solution for contact unit from electrical contact materials to assemblies.