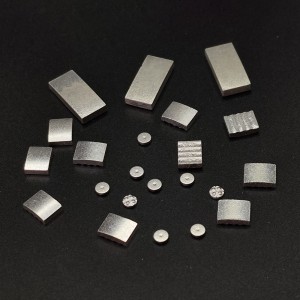

Contact Rivet Material Type and Properties

Contact Rivet Material are widely used in electrical and electronic equipment and have the following characteristics:

● Excellent electrical conductivity: Silver has extremely high electrical conductivity and is one of the materials with the best electrical conductivity among common metals. Silver contacts provide low resistance and efficient current transfer, ensuring a good electrical connection.

● Excellent conductive stability: Silver contacts have excellent conductive stability and can maintain their conductive properties for a long time. It is less susceptible to oxidation, corrosion and arc erosion, maintains stable electrical contact, and reduces heat generated during current transmission.

● High temperature resistance: Silver contacts can maintain stable performance in high temperature environments and have strong resistance to melting and ablation. This makes silver contacts suitable for electrical equipment operating at high temperatures, such as welding equipment, high-power motors, and other high-load equipment.

● Good corrosion resistance: Silver contacts have high corrosion resistance and can maintain good performance in humid environments or in the presence of corrosive gases. This makes silver contacts widely used in environments such as outdoor equipment, marine equipment and chemical industry equipment. It is worth noting that silver contact materials are more expensive than other materials.

Ag-Ni Series (Silver Nickel)

Details

Ag-Ni alloy has excellent electrical conductivity: Since silver (Ag) has extremely high electrical conductivity and nickel (Ni) has higher electrical conductivity, Ag-Ni alloy has excellent electrical conductivity. It can maintain good electrical conductivity under high current and high temperature, and is suitable for conductive connections in various electronic components and electrical equipment. Ag-Ni alloy has good wear resistance and corrosion resistance: nickel has high hardness and corrosion resistance, while silver has good wear resistance. By alloying the two, the Ag-Ni alloy can maintain its wear resistance and corrosion resistance for a long time in harsh environments, such as being used in environments with high temperature, high humidity or corrosive media.

Application

Applications of different types of Ag-Ni Contact Rivets

|

Product name |

Ag Component(wt%) |

Density (g/cm3) |

Conductivity (IACS) |

Hardeness(HV) |

Main rated loads actually used(A) |

Main applications |

|

AgNi(10) |

90 |

10.25 |

90% |

90 |

LOW |

Relay、Contactor、switches |

|

AgNi(12) |

88 |

10.22 |

88% |

100 |

||

|

AgNi(15) |

85 |

10.20 |

85% |

95 |

||

|

AgNi(20) |

80 |

10.10 |

80% |

100 |

||

|

AgNi(25) |

75 |

10.00 |

75% |

105 |

||

|

AgNi(30) |

70 |

9.90 |

70% |

105 |

*Rated load guidelines-low:1~30A,medium:30~100A high:more than 100A

AgNi(15)-H200X

AgNi(15)-Z200X

Ag-SnO2 Series(Silver Tin Oxide)

Details

AgSnO2 alloy has excellent electro-oxidation performance, good electrical contact performance and high-temperature stability. These characteristics make AgSnO2 an ideal contact material, which is widely used in the fields of electrical equipment, electronic devices and automobile industries, providing stable and reliable electrical connection and transmission performance.

Application

Applications of different types of Ag-SnO2 Contact Rivets

| Product name | Ag Component (wt%) |

Density (g/cm3) |

Conductivity (IACS) |

Hardeness(HV) | Main rated loads actually used(A) | Main applications |

| AgSnO2(8) | 92 | 10.00 | 81.5% | 80 | LOW | Switches |

| AgSnO2(10) | 90 | 9.90 | 77.5% | 83 | LOW | |

| AgSnO2(12) | 88 | 9.81 | 75.1% | 87 | Low to medium | Switches、Contactor |

| AgSnO2(14) | 86 | 9.70 | 77.5% | 90 | Low to medium | Contactor |

| AgSnO2(17) | 83 | 9.60 | 68.8% | 90 | Low to medium |

*Rated load guidelines-low:1~30A,medium:30~100A high:more than 100A

AgSnO2(12)-H500X

AgSnO2(12)-Z500X

Ag-SnO2-In2O3 Series(Silver Tin Indium Oxide)

Details

Silver tin oxide Indium oxide is a commonly used contact material consisting of three components: silver (Ag) 、tin oxide (SnO2)and indium oxide (In2O3, 3-5%) . It is manufactured by internal oxidation method. The needle oxide precipitated in the process of internal oxidation is oriented perpendicular to the surface of the contact, which is very beneficial to the performance of the contact. The advantages are as follows:

①High arc erosion resistance for AC and DC applications;

②Low material transferin DC applications;

③Weld resistant and long electricallife;

They are used in low voltage breakers, relays and so on.

Application

Applications of different types of Ag-SnO2-In2O3 Contact Rivets

|

Product name |

Ag Component (wt%) |

Density (g/cm3) |

Conductivity (IACS) |

Hardeness(HV) |

Main rated loads actually used(A) |

Main applications |

|

AgSnO2In2O3(8) |

92 |

10.05 |

78.2% |

90 |

medium |

Switches |

|

AgSnO2In2O3(10) |

90 |

10.00 |

77.1% |

95 |

medium |

Switches、circuit breaker |

|

AgSnO2In2O3(12) |

88 |

9.95 |

74.1% |

100 |

Medium to high |

circuit breaker、Relay |

|

AgSnO2In2O3(14.5) |

85.5 |

9.85 |

67.7% |

105 |

Medium to high |

*Rated load guidelines-low:1~30A,medium:30~100A high:more than 100A

AgSnO2In2O3(12)-H500X

AgSnO2In2O3(12)-H500X

Ag-ZnO Series(Silver Zinc Oxide)

Details

AgZnO alloy is a common contact material consisting of silver (Ag) and zinc oxide (ZnO). Contacts are the key elements used in electrical switches or relays, where current flows to close or open the switch. AgZnO material is widely used in high-load, high-frequency and long-life switchgear because of its excellent electrical properties and wear resistance. The combination of AgZnO makes it have the advantages of both silver and zinc oxide, and has the following characteristics: Excellent electrical conductivity: Silver is a good electrical conductor with low resistance and good current conduction performance, which can effectively reduce resistance loss. The silver particles in the AgZnO material provide an excellent conductive path, enabling the contacts to operate stably under high load conditions. Good wear resistance: Zinc oxide has high hardness and wear resistance, which can effectively resist the wear caused by contact and separation of contacts. The AgZnO material exhibits good durability under frequent switching and high-voltage arc conditions. Oxidation resistance: The zinc oxide layer can form a protective film on the surface of the contact, which can effectively prevent the direct contact between the contact and the external oxygen, thereby slowing down the oxidation speed of silver. This resistance to oxidation prolongs the life of the contacts. Lower arc and spark generation: AgZnO material can effectively suppress the generation of arc and spark, reduce signal interference and loss. This is very important for high frequency and high precision applications. Overall, AgZnO has good electrical conductivity, wear resistance, oxidation resistance, and arc suppression as a contact material, making it widely used in various electrical switch and relay applications.

Application

Applications of different types of Ag-ZnO Contact Rivets

|

Product name |

Ag Component(wt%) |

Density (g/cm3) |

Conductivity (IACS) |

Hardeness(HV) |

Main rated loads actually used(A) |

Main applications |

|

AgZnO(8) |

92 |

9.4 |

69 |

65 |

Low To Medium |

Switches、circuit breaker |

|

AgZnO(10) |

90 |

9.3 |

66 |

65 |

Low To Medium |

|

|

AgZnO(12) |

88 |

9.25 |

63 |

70 |

Low To Medium |

|

|

AgZnO(14) |

86 |

9.15 |

60 |

70 |

Low To Medium |

*Rated load guidelines-low:1~30A,medium:30~100A high:more than 100A

AgZnO(12)-H500X

AgZnO(12)-H500X

Ag alloy Series(Silver alloy)

Details

Fine silver and silver alloys are commonly used materials in various industries due to their unique properties and versatility. Fine silver, also known as pure silver, consists of 99.9% silver and is highly valued for its high electrical and thermal conductivity.

Electrical conductivity: Fine silver and silver alloys are excellent conductors of electricity, making them ideal for applications that require efficient electrical transmission. They are commonly used in electrical contacts, connectors, switches, and various electronic components.

Thermal conductivity: Silver and its alloys possess high thermal conductivity, making them suitable for applications where efficient heat transfer is crucial. They are utilized in heat sinks, thermal interface materials, and thermal management systems.

Ductility and malleability: Silver and silver alloys are highly ductile and malleable, meaning they can be easily shaped and formed into different shapes and sizes. This property makes them ideal for jewelry making, decorative items, and various mechanical components.

Application

Applications of different types of Ag Contact Rivets

|

Product name |

Density (g/cm3) |

Conductivity (IACS) |

Hardeness(HV) |

Main rated loads actually used(A) |

Main applications |

|

|

soft |

hard |

|||||

|

Ag |

10.5 |

60 |

40 |

90 |

Low |

Switches |

|

AgNi0.15 |

10.5 |

58 |

55 |

100 |

Low |

|

*Rated load guidelines-low:1~30A,medium:30~100A high:more than 100A