Exploring the Advantages and Disadvantages of Metal Matrix Composites: A Comprehensive Guide

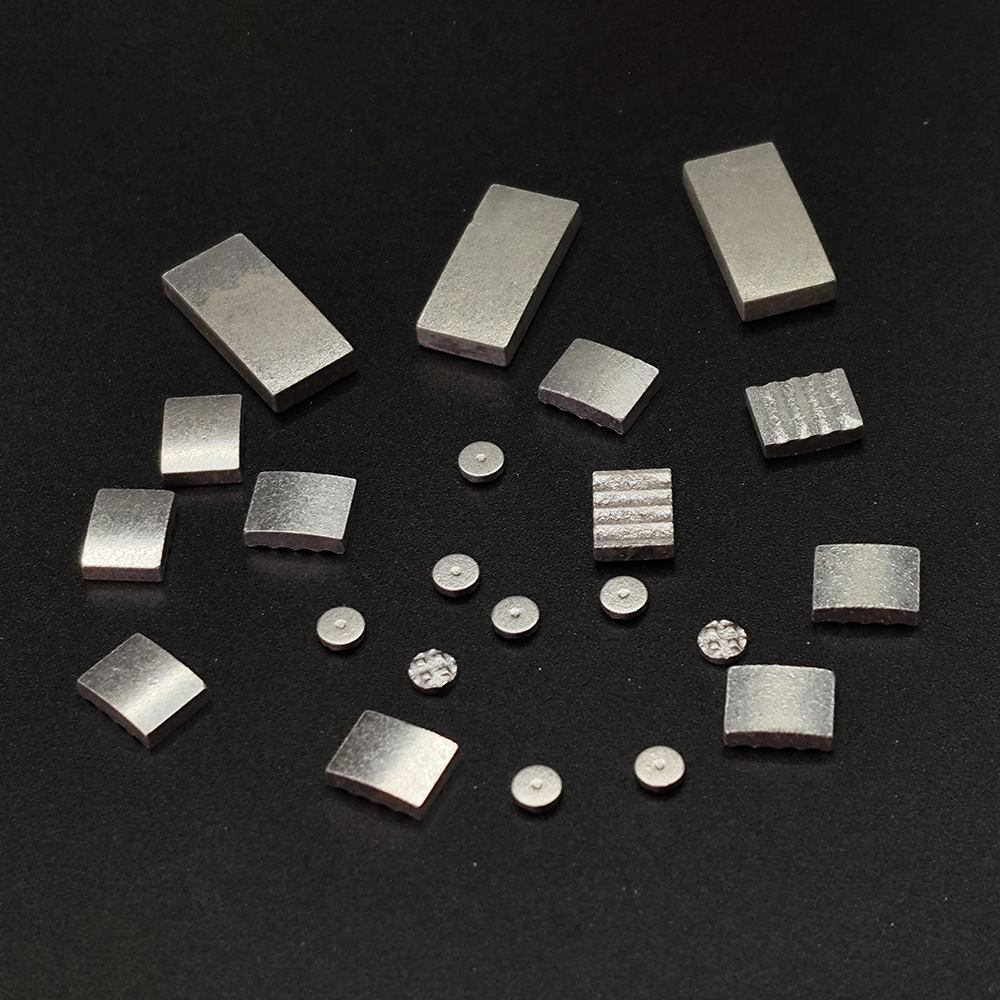

Introducing Metal Matrix Composites: Advantages and Disadvantages Foshan Noble Metal Technology Co., Ltd., a renowned manufacturer, supplier, and factory based in China, proudly presents its cutting-edge Metal Matrix Composites (MMC). With years of expertise in the industry, Noble Metal Technology offers a superior range of MMC products that cater to a wide range of industrial applications. Metal Matrix Composites boast numerous advantages that set them apart from traditional materials. These innovative composites combine the strength of metal with the unique properties of reinforcement materials, such as ceramics or particles, resulting in improved mechanical properties, enhanced wear resistance, and excellent thermal conductivity. By utilizing MMC, industries can benefit from enhanced durability, reduced vibration, and increased thermal stability, making them an ideal choice for demanding applications in automotive, aerospace, and electronics sectors, among others. However, as with any product, there are some considerations to keep in mind. Despite their remarkable properties, Metal Matrix Composites can be relatively expensive compared to conventional materials. Additionally, their fabrication process requires specialized expertise, which may increase production costs. Nevertheless, these drawbacks are easily outweighed by the numerous advantages offered by MMC. Foshan Noble Metal Technology Co., Ltd. prioritizes delivering high-quality Metal Matrix Composites to meet the unique needs of its clients. With their exceptional expertise and state-of-the-art manufacturing facilities, Noble Metal Technology remains committed to providing the industry with top-notch MMC products that exemplify reliability, durability, and performance.

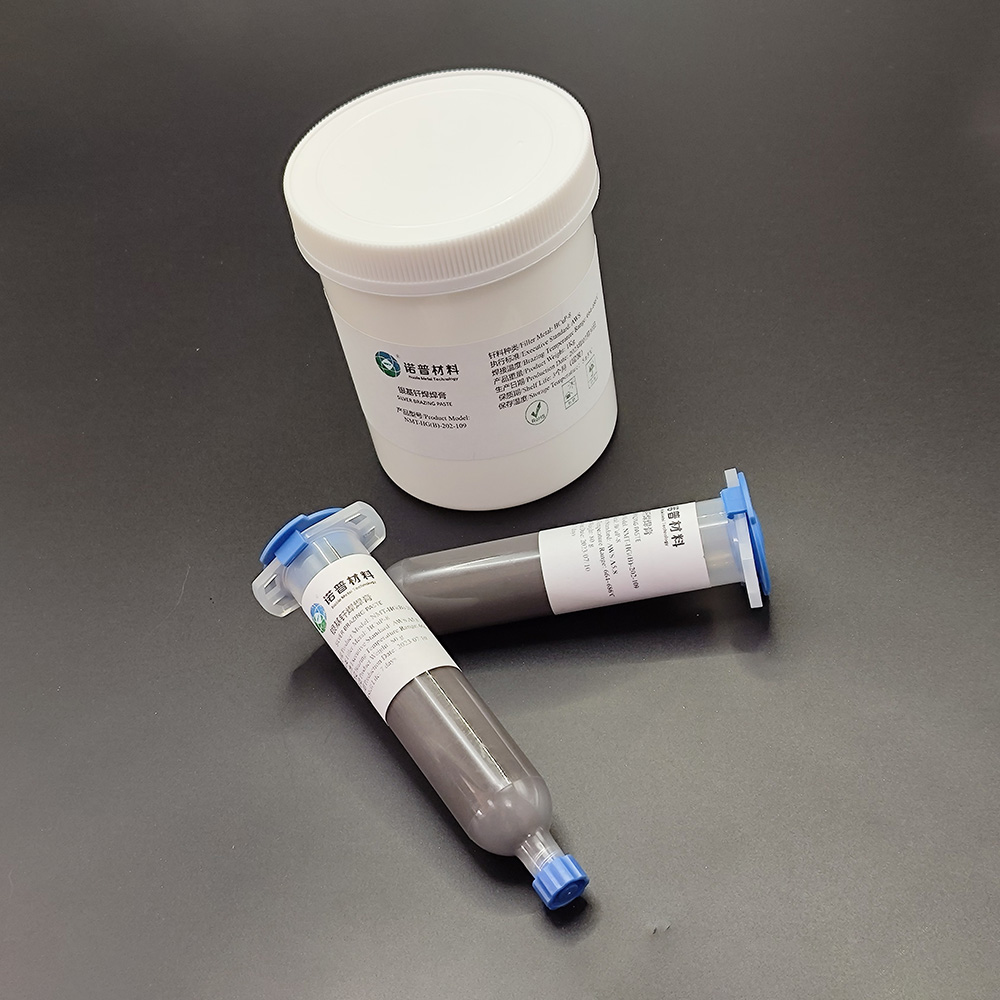

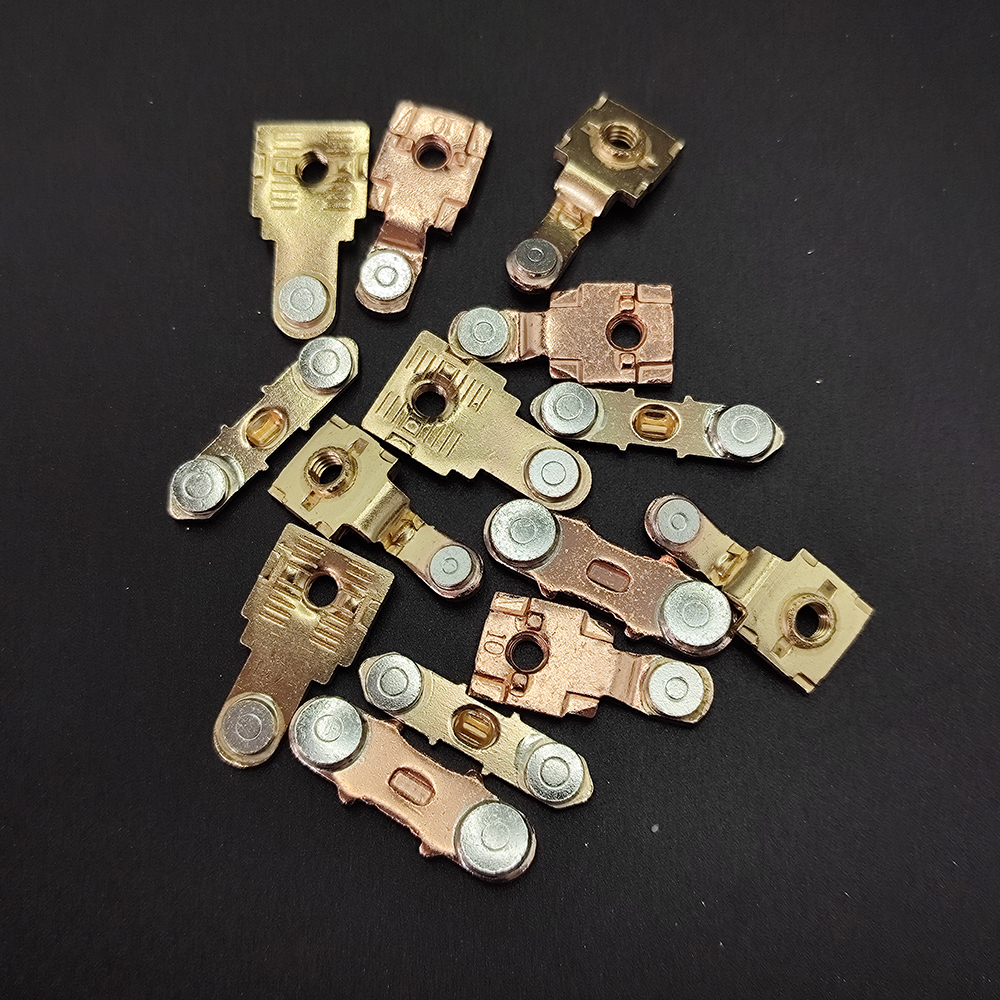

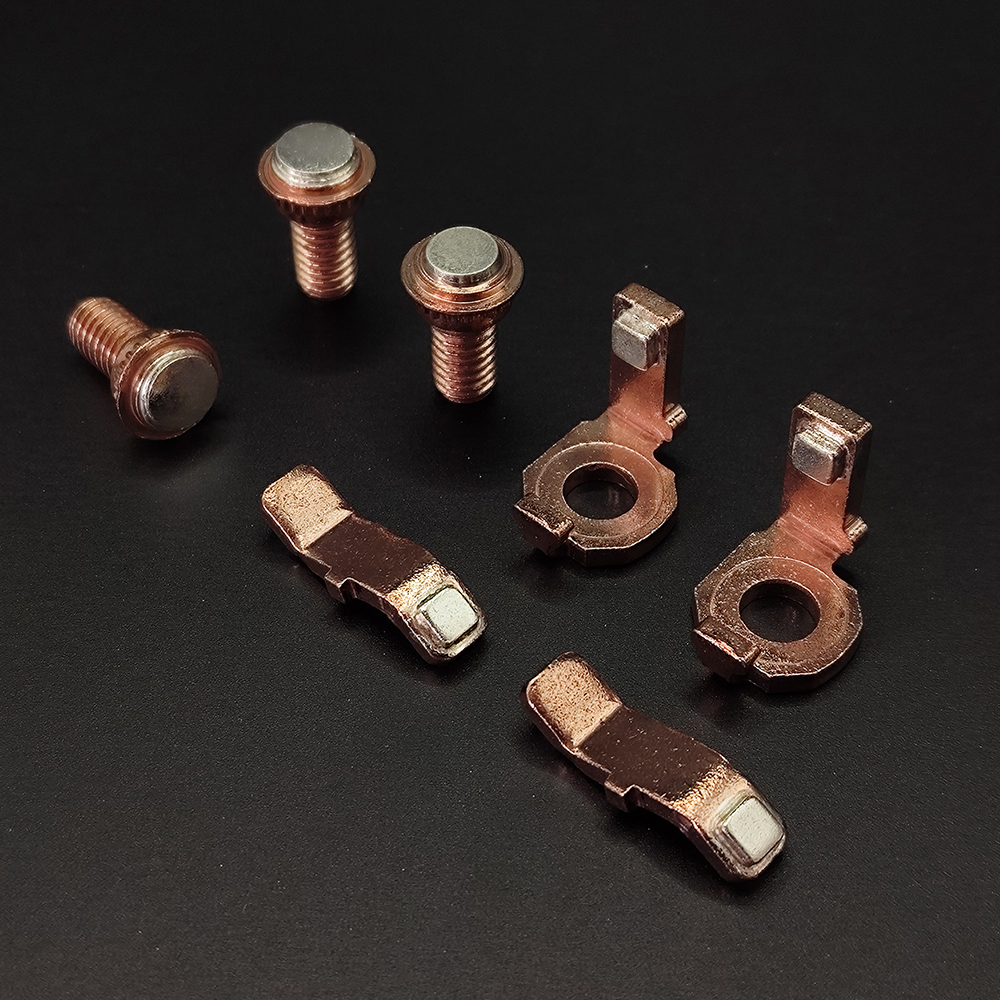

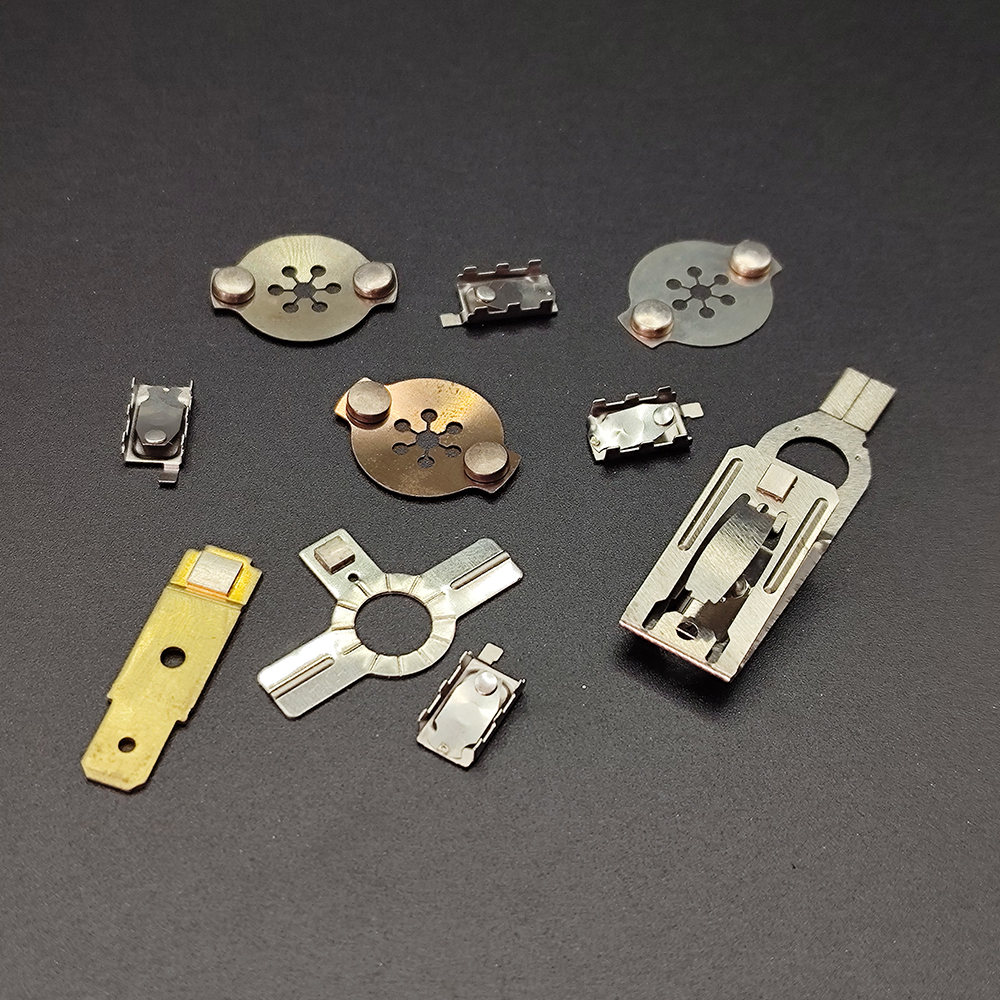

Related Products